Why Acid Etching Will Ruin Your Surface: The Unfortunate Truth

a cautionary tale by armor coatings

Hey there! My name is Brody, your professional garage floor restoration and installation specialist. Over the years, I’ve seen countless garages transformed with these amazing coatings, but I’ve also witnessed some horror stories, especially when folks have tried to prep their surfaces with acid etching. In this article we’ll explore the good, the bad, and the ugly. If you’re considering a new garage floor coating, stick around—I’m about to reveal why acid etching can be a total disaster for your concrete surface and why there’s a much better alternative.

What is Acid Etching?

First things first, let’s talk about what acid etching is. Essentially, acid etching involves applying a solution—usually muriatic acid—onto your concrete surface to clean and roughen it up a bit. The idea is to create a better surface for the coating to adhere to. It sounds simple enough, and many DIY guides recommend it because it’s relatively cheap and easy to do.

People often turn to acid etching because of its perceived benefits. It seems like a relatively inexpensive and quick fix. You can buy the acid at most hardware stores, it’s not too expensive, and the process doesn’t require special equipment. Plus, it feels like you’re doing something substantial to prep your surface.

“Good, cheap, fast — pick two.” – This is acid etching in a nutshell – it’s fast, it’s cheap, but it’s not good. Let’s dive into the science behind it to better understand the true costs.

Avoiding Permanent Surface Damage

Now, here’s where things get tricky. Acid etching can actually cause significant damage to your concrete surface. The acid reacts with the lime in the concrete, creating calcium carbonate. While this might sound harmless, it actually leads to micro-cracking across the entire surface. Over time, these tiny cracks can grow, weakening the whole structure. Imagine investing in a beautiful floor coating system only to have it fail because the foundation was compromised! I remember one client who tried acid etching on their own. By the time I got there to apply the coating, the surface was so brittle and uneven that I had to spend extra hours repairing the damage. It was a costly mistake for them, and a perfect example of why acid etching is more trouble than it’s worth.

Acid etching isn’t just bad for your floor…

Let’s not forget the health and safety risks involved with handling acids. Muriatic acid is highly corrosive and can cause severe burns if it comes into contact with your skin. The fumes are no joke either—they can irritate your eyes and respiratory system. Proper safety gear is a must, but even then, accidents can happen.

Ineffectiveness for Polyaspartic and Epoxy Systems

One of the biggest issues with acid etching is that it often fails to properly prepare the surface for high-performance coatings like polyaspartic and epoxy. Acid etching doesn’t remove all contaminants, and the resulting surface can be uneven. It can break down contaminants like petrol but it does not extract them. As the compounds break down in the acid wash, they seep into the pits and cracks left behind by the etching. This means whatever coating you install will be sitting atop all sorts of things it shouldn’t. This leads to poor adhesion, effervescence, and ultimately a bad finish. Your beautiful new coating could start peeling up in no time.

I’ve seen it all—cracked, uneven surfaces, coatings peeling up, and clients frustrated with their failed DIY attempts. One case that stands out involved a client who had meticulously acid-etched their garage floor, only to find the epoxy peeling up within months. When I inspected the surface, it was clear that the acid hadn’t penetrated evenly, and the surface was full of tiny cracks.

The Superior Alternative: Diamond Grinding

So, what’s the better way? Diamond grinding! This method uses specialized machines with diamond-tipped blades to grind down the surface of the concrete, creating a smooth, even profile perfect for coating.

Diamond grinding preserves the integrity of your concrete surface. Instead of creating micro-cracks like acid etching, it actually strengthens the surface by removing the weak top layer and exposing the solid concrete beneath. The grinding process ensures a uniform surface across the entire area, eliminating the uneven spots that acid etching often leaves behind.

When you’re working with high-performance coatings like polyaspartic and epoxy, surface preparation is key. Diamond grinding creates the ideal profile for these coatings to adhere to, resulting in a finish that’s not only beautiful but also incredibly durable.

Long-Term Cost Savings

While diamond grinding might have a higher upfront cost compared to acid etching, it saves you money in the long run. The durability and longevity of the coating mean fewer repairs and replacements, which translates to less money spent over time. At Armor Coatings we can offer transferable lifetime warranties because of the technical quality of work we perform. We strongly believe there is no substitute for this process.

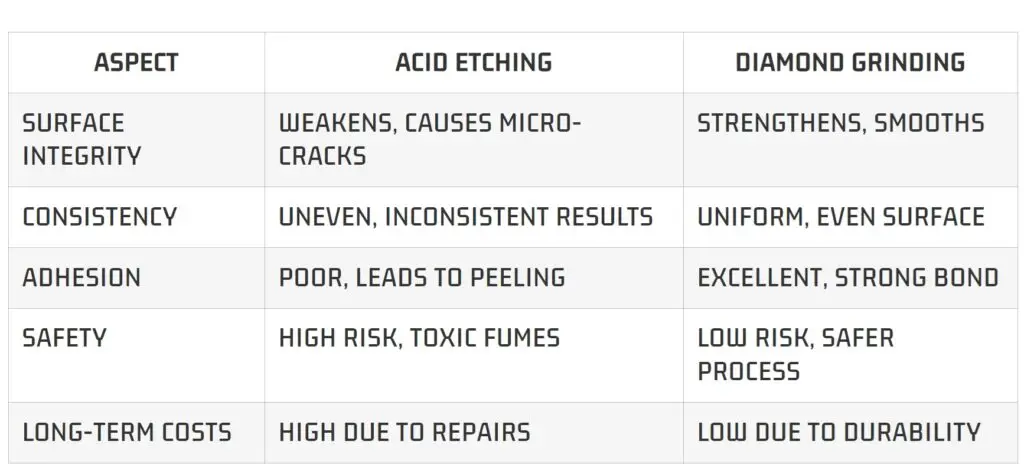

From my professional experience, diamond grinding is hands-down the best method for surface preparation. Here’s a quick comparison chart to highlight the differences:

| Aspect | Acid Etching | Diamond Grinding |

|---|---|---|

| Surface Integrity | Weakens, causes micro-cracks | Strengthens, smooths |

| Consistency | Uneven, inconsistent results | Uniform, even surface |

| Adhesion | Poor, leads to peeling | Excellent, strong bond |

| Safety | High risk, toxic fumes | Low risk, safer process |

| Long-Term Costs | High due to repairs | Low due to durability |

When you choose Armor Coatings, here’s what you can expect:

-

Assessment: We assess the condition of your concrete surface, its hardness, and the moisture content of your slab to determine what products are right for your floor.

-

Grinding: Using diamond-tipped orbital planetary grinders, we meticulously grind down the entire surface. We will never use acid.

-

Cleaning: The area is thoroughly cleaned using an extremely powerful dust extractor to remove any dust and debris from the porous surface of the prepared concrete.

-

Coating and Flake Application: Finally, we apply your chosen coating over the professionally prepared slab and broadcast a beautiful, uniform layer of flake before scraping and applying our top shelf, high solids polyaspartic top-coat.

To sum it up, acid etching is a risky, outdated method that can do more harm than good. For a durable, beautiful garage floor coating, diamond grinding is the way to go. It preserves the integrity of your surface, ensures better adhesion, and saves you money in the long run. If you’re ready to transform your garage floor, don’t hesitate to reach out. I’m here to help you every step of the way.

FAQs

Common Questions

Q: Isn’t acid etching cheaper?

A: While acid etching might seem cheaper upfront, the potential for damage and the likelihood of needing repairs make it more expensive in the long run.

Q: Can I do the diamond grinding myself?

A: Diamond grinding requires specialized equipment and expertise. It’s best to hire a professional to ensure the job is done correctly and safely.

Contact Information

If you have any questions or are ready to get started on your garage floor transformation, feel free to contact me at [513-461-4890] or you can email me at [email protected]. For more information, check out the rest of my website where you can find additional resources and information on surface preparation and coatings.

Let’s get your garage floor looking amazing and lasting for years to come!